BAUM TF-Evolution

High operational reliability for your systems for least possible permeation

Linings made of fluoropolymer involve the risk of permeation, i.e. the penetration of the lining by the medium. In the field of piping, the medium as well as the working conditions are of decisive importance for the intensity of the permeation effect. A standard PTFE lining is suitable for many media and designed for a lifetime durability. However, certain media such as chlorine compounds have properties that may result in permeation. They penetrate the lining material and impair its mechanical properties. As a result, for example corrosion effects may occur which could endanger the operational safety of the pipeline.

BAUM TF-Evolution for highest permeation density

BAUM TF-Evolution was developed in the laboratory and during long-term tests together with our customers under real working conditions. The BAUM TF-Evolution lining significantly reduces permeation when exposed to critical media. The permeation resistance of customized products can be tailored to the respective working conditions of the customer. In this way, individual require- ments are met flexibly and reliably.

TF-Evolution reduces

- a discolouration of the lining.

- blistering of the lining.

- corrosion effects of the pipeline.

TF-Evolution increases

- the permeation density for the protection of the steel material.

- the operational safety of the pipeline.

What does permeation mean?

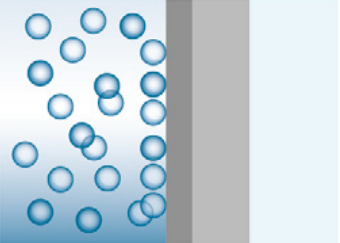

Permeation is a process in which a substance penetrates a solid on a molecular basis.

This permeation process is induced by a pressure or concentration gradient in the individual body. Without the effect of external influences, the substance always moves in the direction of lower concentration or lower pressure.

Permeation takes place in several stages:

1. Adsorption

The substance accumu- lates on the surface. This can occur from the gaseous phase or in direct contact with the liquid or solid material.

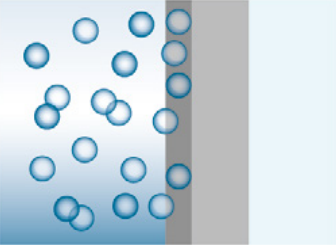

2. Absorption

The substance is absorbed.

3. Diffusion

At this stage, the pene- tration of the material on a molecular level begins. The substance penetrates the solid through pores or molecular spaces.

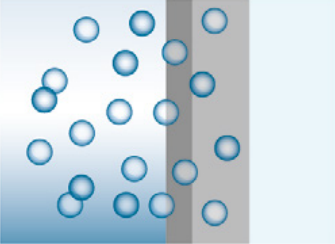

4. Desorption

After the molecules have penetrated the solid, they diffuse away from the surface.

Our solution for reducing permeation

BAUM TF-Evolution – maximum reliability due to extended longevity

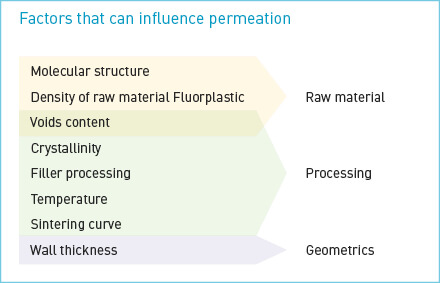

The permeation density is mainly dependent on the properties of the lining. The raw material used as well as the manufacturing processes are the decisive criteria in the development of permeation-reducing linings (see fig.). BAUM TF-Evolution is made from modified PTFE and by means of specially adapted processing methods. With TF-Evolution, BAUM has succeeded in responding individually to the key factors and thus implementing special customer requirements.

By using modified fluoroplastics with a denser microstructure as well as specially adapted processing techniques, linings have been developed which, due to their lower permeability, offer a significantly longer durability when exposed to critical media and operating conditions. Long-term tests in the laboratory as well as under real working conditions at various customers prove the considerably stronger permeation properties of BAUM TF-Evolution in comparison to standard materials.

BAUM TF-Evolution: High permeation density for maximum durability.

Long-term tests for the safety of your installations

Long-term tests in the laboratory and with users under real conditions show the following: Compared to the lining with standard PTFE, the lining with BAUM TF-Evolution has a considerably extended longevity when used with highly permeative media and under different working conditions.

Test results for HCl applications after 18 months of use

Test „HCl – P>3 bar - t ~ 160-180°C“

Standard PTFE (under normal operating conditions)

Medium with low tendency to permeation

The lining has slightly discoloured, but no blisters occur. The steel material was not affected.

Standard PTFE

Medium HCl

The standard quality darkens under critical media and conditions and a large number of blisters occur throughout. The steel has already been affected on the inside.

BAUM TF-Evolution, paste-extruded quality Medium HCl

The lining has slightly discoloured, only very few blisters occur. The steel is not affected.

BAUM TF-Evolution, injection moulding process Medium HCl

The lining has slightly discoloured, no blisters occur. The steel is not affected.

Tailor-made solutions for your demand

Our customers’ individual applications require specific lining qualities

Advantages of TF-Evo

- Higher permeation density

- Increased operational safety

- Extended longevity of the pipelines

- Lower investment costs compared to special metal alloys or glass pipelines

Depending on material selection, liner dimensioning and processing, we imple- ment the most appropriate solution for your requirements – for an extended longevity. BAUM TF-Evolution (BAUM TF-Evo) can be used for the complete BAUM product range in the piping sector. Just get in touch with us!

Always state-of-the-art

New and changing media require a constant adaptation of the various control variables, such as raw materials and their processing.

Here you can download our TF-Evolution brochure: