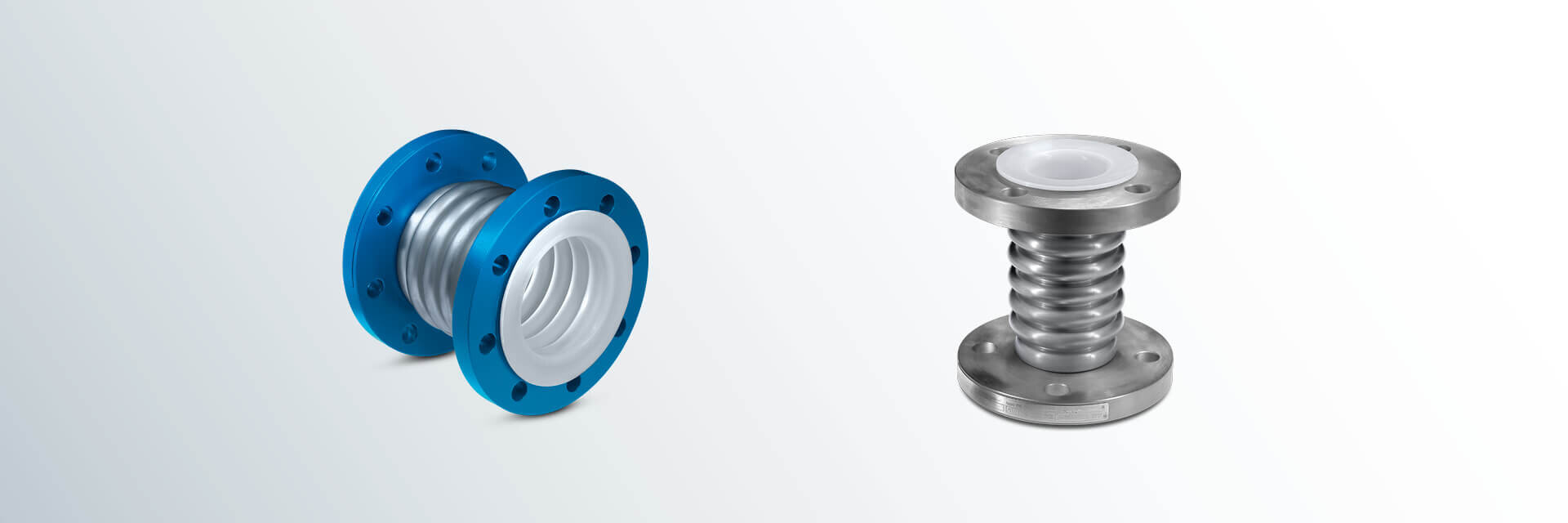

ANSI PTFE Lined Stainless Steel Expansion Joints (Class 150)

In case of high pressures and hight temperatures. our PTFE Lined Stainless Steel Expansion Joints are the right choice for your pipes. Stainless Steel Expansion Joints are the most stable expansion joints.

Flange materials:

- carbon steel

- stainless steel

Lining material:

- PTFE (virgin or conductive)

Bellow material:

- stainless steel

Flanges:

- loose-loose

Other pressure rating:

- Class 300

Special features:

- earthing stud/lug

Optional extras:

- final painting (flanges)

NPS

| L

(mm) | Stroke ± (mm) | Axial spring rate (N/mm) | Vacuum resistance (105 Pa) at | d4

(mm) | No. of bolts x thread (UNC) | Weights

(ca. kg/pc.) | |

23° C | 160° C | |||||||

1¼“ | 145 | 4.5 | 260 | 0.15 | 0.30 | 63.5 | 4 x ½“ | 4.0 |

1¼“ | 220 | 9.0 | 130 | 0.15 | 0.30 | 63.5 | 4 x ½“ | 4.0 |

1½“ | 155 | 5.5 | 272 | 0.15 | 0.30 | 73.0 | 4 x ½“ | 5.0 |

1½“ | 240 | 11.0 | 136 | 0.15 | 0.30 | 73.0 | 4 x ½“ | 5.0 |

2“ | 177 | 6.5 | 276 | 0.15 | 0.30 | 92.1 | 4 x ⅝“ | 6.0 |

2“ | 292 | 13.5 | 195 | 0.15 | 0.30 | 92.1 | 4 x ⅝“ | 6.0 |

2½“ | 179 | 8.5 | 234 | 0.15 | 0.30 | 104.8 | 4 x ⅝“ | 7.0 |

2½“ | 285 | 16.0 | 173 | 0.15 | 0.30 | 104.8 | 4 x ⅝“ | 7.5 |

3“ | 183 | 10.0 | 220 | 0.15 | 0.30 | 127.0 | 4 x ⅝“ | 7.5 |

3“ | 273 | 17.5 | 178 | 0.15 | 0.30 | 127.0 | 4 x ⅝“ | 8.5 |

4“ | 178 | 10.0 | 365 | 0.15 | 0.30 | 157.2 | 8 x ⅝“ | 10.0 |

4“ | 266 | 20.0 | 183 | 0.15 | 0.30 | 157.2 | 8 x ⅝“ | 11.5 |

5“ | 221 | 14.5 | 290 | 0.25 | 0.40 | 185.7 | 8 x ¾“ | 13.0 |

5“ | 363 | 25.0 | 290 | 0.25 | 0.40 | 185.7 | 8 x ¾“ | 15.0 |

6“ | 248 | 15.0 | 560 | 0.25 | 0.40 | 215.9 | 8 x ¾“ | 17.0 |

6“ | 388 | 30.0 | 280 | 0.25 | 0.40 | 215.9 | 8 x ¾“ | 20.0 |

8“ | 246 | 21.0 | 412 | 0.35 | 0.50 | 269.9 | 8 x ¾“ | 24.0 |

8“ | 418 | 39.0 | 335 | 0.35 | 0.50 | 269.9 | 8 x ¾“ | 30.0 |

10“ | 243 | 22.0 | 525 | 0.40 | 0.60 | 323.8 | 12 x ⅞“ | 32.0 |

10“ | 392 | 40.5 | 269 | 0.40 | 0.60 | 323.8 | 12 x ⅞“ | 35.0 |

12“ | 287 | 27.5 | 480 | 0.50 | 0.75 | 381.0 | 12 x ⅞“ | 37.0 |

12“ | 429 | 47.5 | 352 | 0.50 | 0.75 | 381.0 | 12 x ⅞“ | 43.0 |

14“ | 296 | 30.0 | 460 | 0.50 | 0.75 | 412.8 | 12 x 1“ | 51.0 |

14“ | 407 | 46.0 | 378 | 0.50 | 0.75 | 412.8 | 12 x 1“ | 57.0 |

16“ | 290 | 26.0 | 713 | 0.70 | 0.90 | 469.9 | 16 x 1“ | 68.0 |

16“ | 434 | 52.0 | 357 | 0.70 | 0.90 | 469.9 | 16 x 1“ | 75.0 |

18“ | 328 | 35.0 | 548 | 0.70 | 0.90 | 533.4 | 16 x 1⅛“ | 76.0 |

18“ | 535 | 65.0 | 430 | 0.70 | 0.90 | 533.4 | 16 x 1⅛“ | 97.0 |

20“ | 309 | 28.0 | 955 | - | - | 584.2 | 20 x 1⅛“ | 97.0 |

20“ | 509 | 63.0 | 425 | - | - | 584.2 | 20 x 1⅛“ | 113.0 |

24“ | 336 | 35.0 | 548 | - | - | 692.2 | 20 x 1¼“ | 118.0 |

24“ | 484 | 63.0 | 305 | - | - | 692.2 | 20 x 1¼“ | 130.0 |

Different nominal pipe sizes and

total lengths on request.

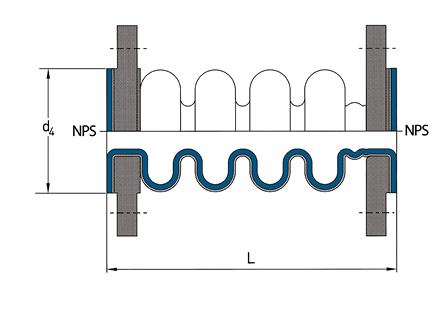

L = Total length

d4 = Raised face diameter

Technical data valid for the pressure rating Class 150.