DIN Instrument Tees (PN 10)

Instrument Tees, also known as gauge connections, are the one-piece solution with PFA or PP lining for the connection to your measuring devices. In case of narrow space, also useable as short tee.

Materials:

- carbon steel

- stainless steel

Lining materials:

- PFA (virgin or conductive)

- PP

Other pressure levels:

- PN 16

- PN 25

- PN 40

Special features:

- earthing stud/lug

- vent hole extension

Optional extras:

- final painting

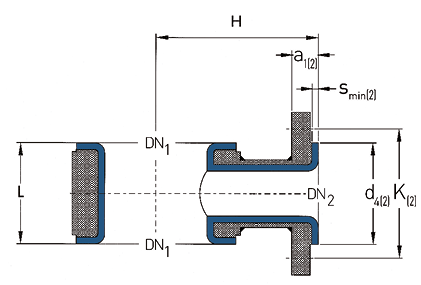

DN1

| DN2

| L

(mm) | H

(mm) | d4(2)

(mm) | K(2)

(mm) | smin (2)

(mm) | a1(2)

(mm) | No. of bolts x thread DN2 | Weights (ca. kg/piece)

|

25 | 15 | 50 | 90 | 45 | 65 | 4.0 | 20.0 | 4 x M12 | 2.0 |

25 | 20 | 50 | 90 | 58 | 75 | 4.0 | 22.0 | 4 x M12 | 2.4 |

25 | 25 | 50 | 90 | 68 | 85 | 4.0 | 22.0 | 4 x M12 | 2.6 |

32 | 15 | 50 | 100 | 45 | 65 | 4.0 | 20.0 | 4 x M12 | 2.3 |

32 | 20 | 50 | 100 | 58 | 75 | 4.0 | 22.0 | 4 x M12 | 2.8 |

32 | 25 | 50 | 100 | 68 | 85 | 4.0 | 22.0 | 4 x M12 | 3.0 |

40 | 15 | 50 | 110 | 45 | 65 | 4.0 | 20.0 | 4 x M12 | 2.7 |

40 | 20 | 50 | 110 | 58 | 75 | 4.0 | 22.0 | 4 x M12 | 3.1 |

40 | 25 | 50 | 110 | 68 | 85 | 4.0 | 22.0 | 4 x M12 | 3.3 |

40 | 40 | 75 | 110 | 88 | 110 | 4.0 | 22.0 | 4 x M16 | 5.4 |

50 | 15 | 50 | 115 | 45 | 65 | 4.0 | 20.0 | 4 x M12 | 3.2 |

50 | 20 | 50 | 115 | 58 | 75 | 4.0 | 22.0 | 4 x M12 | 3.7 |

50 | 25 | 50 | 115 | 68 | 85 | 4.0 | 22.0 | 4 x M12 | 3.9 |

50 | 40 | 75 | 115 | 88 | 110 | 4.0 | 22.0 | 4 x M16 | 6.3 |

50 | 50 | 90 | 115 | 102 | 125 | 4.0 | 22.0 | 4 x M16 | 7.6 |

65 | 15 | 50 | 125 | 45 | 65 | 4.0 | 20.0 | 4 x M12 | 4.0 |

65 | 20 | 50 | 125 | 58 | 75 | 4.0 | 22.0 | 4 x M12 | 4.4 |

65 | 25 | 50 | 125 | 68 | 85 | 4.0 | 22.0 | 4 x M12 | 4.6 |

65 | 40 | 75 | 125 | 88 | 110 | 4.0 | 22.0 | 4 x M16 | 8.3 |

65 | 50 | 90 | 125 | 102 | 125 | 4.0 | 22.0 | 4 x M16 | 9.1 |

80 | 15 | 50 | 135 | 45 | 65 | 4.0 | 20.0 | 4 x M12 | 4.5 |

80 | 20 | 50 | 135 | 58 | 75 | 4.0 | 22.0 | 4 x M12 | 5.0 |

80 | 25 | 50 | 135 | 68 | 85 | 4.0 | 22.0 | 4 x M12 | 5.2 |

80 | 40 | 75 | 135 | 88 | 110 | 4.0 | 22.0 | 4 x M16 | 8.3 |

80 | 50 | 90 | 135 | 102 | 125 | 4.0 | 22.0 | 4 x M16 | 11.2 |

100 | 15 | 50 | 150 | 45 | 65 | 4.0 | 20.0 | 4 x M12 | 5.0 |

100 | 20 | 50 | 150 | 58 | 75 | 4.0 | 22.0 | 4 x M12 | 5.4 |

100 | 25 | 50 | 150 | 68 | 85 | 4.0 | 22.0 | 4 x M12 | 5.7 |

100 | 40 | 75 | 150 | 88 | 110 | 4.0 | 22.0 | 4 x M16 | 9.1 |

100 | 50 | 90 | 150 | 102 | 125 | 4.0 | 22.0 | 4 x M16 | 12.2 |

125 | 15 | 50 | 160 | 45 | 65 | 4.0 | 20.0 | 4 x M12 | 6.2 |

125 | 20 | 50 | 160 | 58 | 75 | 4.0 | 22.0 | 4 x M12 | 6.7 |

125 | 25 | 50 | 160 | 68 | 85 | 4.0 | 22.0 | 4 x M12 | 6.9 |

125 | 40 | 75 | 160 | 88 | 110 | 4.0 | 22.0 | 4 x M16 | 11.0 |

125 | 50 | 90 | 160 | 102 | 125 | 4.0 | 22.0 | 4 x M16 | 13.3 |

150 | 15 | 50 | 180 | 45 | 65 | 4.0 | 20.0 | 4 x M12 | 6.9 |

150 | 20 | 50 | 180 | 58 | 75 | 4.0 | 22.0 | 4 x M12 | 7.4 |

150 | 25 | 50 | 180 | 68 | 85 | 4.0 | 22.0 | 4 x M12 | 7.6 |

150 | 40 | 75 | 180 | 88 | 110 | 4.0 | 22.0 | 4 x M16 | 12.1 |

150 | 50 | 90 | 180 | 102 | 125 | 4.0 | 22.0 | 4 x M16 | 14.7 |

200 | 15 | 50 | 210 | 45 | 65 | 4.0 | 20.0 | 4 x M12 | 9.5 |

200 | 20 | 50 | 210 | 58 | 75 | 4.0 | 22.0 | 4 x M12 | 9.9 |

200 | 25 | 50 | 210 | 68 | 85 | 4.0 | 22.0 | 4 x M12 | 10.1 |

200 | 40 | 75 | 210 | 88 | 110 | 4.0 | 22.0 | 4 x M16 | 16.1 |

200 | 50 | 90 | 210 | 102 | 125 | 4.0 | 22.0 | 4 x M16 | 19.6 |

250 | 25 | 50 | 240 | 68 | 85 | 4.0 | 22.0 | 4 x M12 | 13.7 |

250 | 40 | 75 | 240 | 88 | 110 | 4.0 | 22.0 | 4 x M16 | 21.7 |

250 | 50 | 90 | 240 | 102 | 125 | 4.0 | 22.0 | 4 x M16 | 26.4 |

300 | 25 | 90 | 340 | 68 | 85 | 4.0 | 22.0 | 4 x M12 | 27.5 |

300 | 40 | 110 | 340 | 88 | 110 | 4.0 | 22.0 | 4 x M16 | 34.8 |

300 | 50 | 120 | 340 | 102 | 125 | 4.0 | 22.0 | 4 x M16 | 38.5 |

350 | 25 | 90 | 375 | 68 | 85 | 4.0 | 22.0 | 4 x M12 | 43.2 |

350 | 40 | 110 | 375 | 88 | 110 | 4.0 | 22.0 | 4 x M16 | 54.2 |

350 | 50 | 120 | 375 | 102 | 125 | 4.0 | 22.0 | 4 x M16 | 59.7 |

400 | 25 | 90 | 390 | 68 | 85 | 4.0 | 22.0 | 4 x M12 | 48.3 |

400 | 40 | 110 | 390 | 88 | 110 | 4.0 | 22.0 | 4 x M16 | 60.5 |

400 | 50 | 120 | 390 | 102 | 125 | 4.0 | 22.0 | 4 x M16 | 66.6 |

450 | 25 | 90 | 425 | 68 | 85 | 4.0 | 22.0 | 4 x M12 | 51.1 |

450 | 40 | 110 | 425 | 88 | 110 | 4.0 | 22.0 | 4 x M16 | 64.0 |

450 | 50 | 120 | 425 | 102 | 125 | 4.0 | 22.0 | 4 x M16 | 70.6 |

500 | 25 | 90 | 450 | 68 | 85 | 4.0 | 22.0 | 4 x M12 | 66.5 |

500 | 40 | 110 | 450 | 88 | 110 | 4.0 | 22.0 | 4 x M16 | 83.1 |

500 | 50 | 120 | 450 | 102 | 125 | 4.0 | 22.0 | 4 x M16 | 91.5 |

Different nominal pipe sizes, total lengths and

other construction types on request.

L = Total length

H = Overall height

d4 = Raised face diameter

K = Bolt circle diameter

smin = Minimum flare thickness

a1 = Minimum length with fixed flange (Type 11)

and smin

Technical data valid for the pressure level PN 10.

a1 depends on construction type and lining thickness.

| DN | Lining thickness | Possible vacuum | |||

| standard | thick-walled | 23°C | 150°C | 200°C | |

| 25 | |||||

| 40 | |||||

| 50 | |||||

| 80 | |||||

| 100 | |||||

| 150 | |||||

| 200 | |||||

| 250 | |||||

| 300 | |||||

| = | full vacuum | |

| = | limited vacuum | |

| = | no vacuum | |

| Please refer to the next higher nominal pipe size if your nominal pipe size is not listed. | ||